Mechanical Assembly Method

Ir Mechanical installation ası is a method of attaching stone cladding materials to the building surface with stainless steel elements called hooks or anchors. In this system, the weight of each stone is transferred individually to the building surface. With this system, it is possible to disassemble any stone after assembly and to replace it with other materials without damaging the others in any way. The stones should never be mounted to the exterior façade of the multi-storey buildings with the gluing method. Due to the expansion and contraction of the heat differences of different materials and the factors such as sitting and earthquake which may occur in the building, the risk of falling stones is very high. In the mechanical mounting system, different anchoring methods are selected depending on the character of the surface, stone size, stone thickness and building height. The mounting system is specially designed and applied for each building. The system should be completely stainless. Stainless steel elements to be used in the system should be AISI 316 or 304 quality standards.

Dot Anchor System

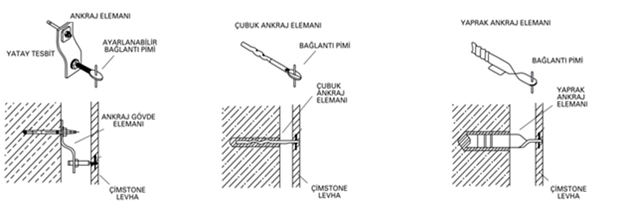

This system is divided into two as H body ZAnkraj and Leaf Anchor system. In places where the surface to be coated has bearing properties (eg: gross concrete, reinforced concrete curtain, column beam, etc.), H body Z Anchor system is applied. On these surfaces, ZAnkrajs are mounted directly to the surface by means of steel dowels and each stone is attached to the ZAnkrajlar with four stainless pins. The distance between the surface to be covered and the back side of the stone can be between 3 cm and 9 cm. If the surface does not have surface bearing properties (aerated concrete, briquettes, bricks, etc.) and the stone dimensions are small, the Leaf Anchor system is applied. For these surfaces, stainless steel blades with a Leaf Anchor are fixed to the wall with a diameter of 24 mm and a depth of approximately 70 mm. In this system, the distance between the surface to be covered and the back of the stone can be between 1.5 cm and 6 cm.

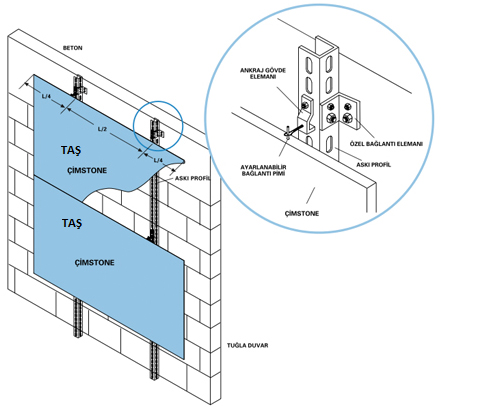

Profiled Anchor System

This system is not a carrier of the surface to be coated (gas concrete, briquettes, bricks, etc.); It is applied when the surface between the surface to be coated and the stone is too open (such as isolation, deception or aesthetic reasons) and when the stones to be coated are large size. Profiles are fixed on the beams of reinforced concrete slabs, with two pieces behind each stone. The coating materials are fitted with Z anchors to these profiles as in the H-frame Z system. In this system, the distance between the surface to be covered and the back side of the stone should be at least 7 cm and maximum 22 cm.

Application Standards

• The thickness of the products to be covered by mechanical assembly to be determined according to the type of wall on the exterior wall (feature of the carrier not having a carrier / or carrier) min. 2 cm. The floor heights, openings and the locations of the bearing elements are decisive in the selection of the material dimensions to be used in the coating (width / length / thickness).

• The dimensions of the stones should be large enough for the assembler to carry. Therefore, if the stone area is not larger than 0.5 square meters, it will facilitate the installation of the stone.

• The shape of the stone should be as close to 1/2 rectangle or square as possible. Very thin, long stones can be broken by stretching.

• In determining the cross-sections of the anchor elements, the length of the stone, the distance between the stone wall and the height of the building should be determined.

• Leave the ventilation gap between the coated surface and the stone. This process is a requirement of the mechanical system as well as provides natural heat and water insulation. In addition, this space can be used for additional heat (with extrudepoliestrene material) and water (with PVC based membrane).

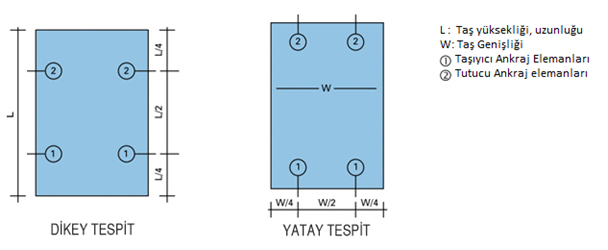

• Stones should be fixed at the top and bottom edge. However, in case of necessity, fixation is carried out on the side edges. When attaching the anchors to the side edges, the two-fold load will be taken into account for each anchor.

• For the assembly made from the lower and upper edges, each of the lower anchors at the lower edge shall take half of the horizontal load (suction and pressure wind load) of the stone in which the vertical stone is below or below the vertical load.

• The anchor hole to be fixed at the top / side or side edges must be opened at distance L / 4.

• The anchor element carries the weight of the top stone and the bottom stone.

• When determining the cross sections of the mechanical elements, it is necessary to take into consideration the dead load of the system, the earthquake load and the suction and pressure loads of the wind. Depending on wind loads, tensile and pressure inspections must be carried out.

• Material installation should be done with a minimum of 5 mm in horizontal and vertical.

• Minimum dimensions of steel pins that attach stones to anchors; 50 mm in diameter, 5 mm in diameter and should be mounted with a plastic capsule so that it can receive additional stresses (such as thermal expansions, building settlements, earthquake loads).

• The geometry of the system ensures a low load on the anchor and allows the use of smaller diameter anchors.

• The system allows height adjustment in 3 axes (x, y, z).

• With anchor pin To compensate for different thermal expansions of stone or marble, use plastic capsule or fill with silicone.

• Fill horizontal and vertical joints with silicone or polyurethane sealant, or be left open for ventilation.

• If the joints are filled, some horizontal joints must be left open to prevent corrosion.

• In the maintenance and protection of the applied areas, a water-soluble neutral cleaning material and soft, non-destructive care materials should be used.